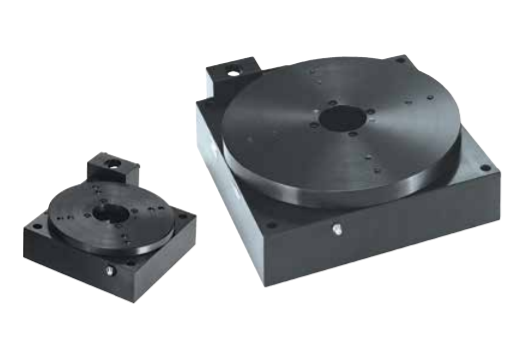

200RT Series Rotary Tables

The 200RT Series Rotary Tables are designed for precise motor-driven rotary positioning and indexing. These tables are designed to function independently or in conjunction with linear tables used for precision automation applications. Their low profile design minimizes stack height in multi-axis configurations and enables them to fit in many places where other motorized rotary devices cannot. Models are available in 5, 6, 8, 10, or 12 inch diameters and are offered with four gear ratios making it convenient to match size, speed, and load requirements.

• Highly repeatable indexing (12 arc sec.)

• Load capacities to 200 lbs.

• 360 degrees continuous travel

• Performance tested worm gear drive

• Selectable table sizes and drive ratio

• Table diameters of 5, 6, 8, 10, or 12 inch

• Dual race angular contact support bearing

• High resolution rotary encoder for direct positional feedback

When starting a new linear and rotary motion project, In-Position Technologies engineers start by reviewing the key requirements to determine the optimum positioner for the job. They perform all necessary engineering calculations to make sure the positioners perform as required, within customer specification, and without unnecessary cost. They will also recommend the appropriate controllers and drives that will best fit the application.

This includes:

• Motor torque, speed, and inertia matching

• Ensuring compatibility with the motor drive and available power

• Specifying the appropriate feedback device, encoder (incremental vs. absolute), resolver, etc…

• Verifying mounting compatibility, form factor checks, etc…

• Ensuring all necessary accessories are also specified

When ordering 200RT Series Rotary Tables as a part of a full system, IP Tech engineers review the solution to ensure:

• All parts and accessories necessary for a complete working solution are included

• All components have been checked and verified to work together as a system

• The selected components will perform as required by the project specifications