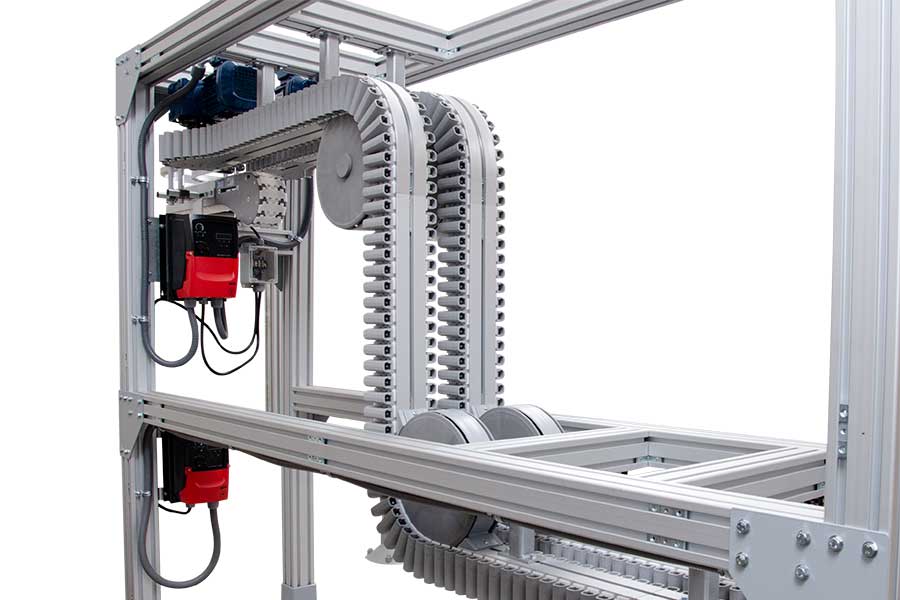

Gripper Elevator Conveyors

QC Conveyors specializes in modular conveyor systems with superior automation capabilities, offering flexible, durable, and easy-to-integrate solutions for material handling.

Gripper Elevator Conveyors grip products between two parallel conveyors and elevate or lower them to a different level of your plant, over an aisle, or to remove products from a puck.

• Modular Design

• Plastic Chain

• T-Slot Design

• Gripper Chain

• Adjustable Width

• Plastic Chain Technology by Modu

When starting a new conveyor project, In-Position Technologies engineers begin by reviewing the essential requirements to determine the optimum specification need from the conveyor to meet the transport requirement. They perform all necessary engineering assessments to make sure the conveyor and its auxiliary equipment perform as required, within customer specifications, and without unnecessary cost. They will also recommend the appropriate controllers, the electric source, the optimum layout of the path, motor and drive/gearbox configuration, and sensor (safety, logistic bar code reader) that fit the application.

This includes:

• Calculating payload, reach, speed, cycle time, length and width of path requirement

• Ensuring compatibility with the current ERP system

• Specifying the appropriate feedback device (sensors, relays, vision system/barcode reader)

• Verifying location compatibility, form factor checks, etc.

• Ensuring all necessary auxiliary equipment is also specified

When ordering the Gripper Elevator Conveyors as a part of a full system, IP Tech engineers review the solution to ensure:

• All parts and attachments necessary for a complete working solution are included

• All components have been checked and verified to work together as a system

• The selected components will perform as required by the project specifications