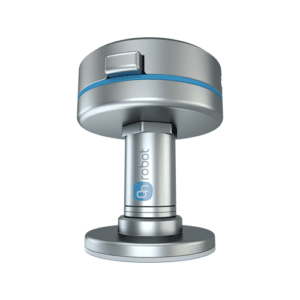

Hex 6-Axis Force/Torque Sensors

OnRobot delivers a full line of plug-and-produce end-of-arm tooling (EoAT) for collaborative applications. Their innovative grippers, sensors, and tool changers help manufacturers gain the full advantages of collaborative and lightweight industrial robots, including ease of use, cost-effectiveness, and safety alongside human workers. View Additional OnRobot Products

OnRobot Hex 6-axis force torque sensors provide accurate force and torque measurements along all 6 axes. This gives you precise control when it comes to difficult assembly, polishing, sanding or deburring jobs. Additionally, the HEX software includes path recording, force control and special features for insertion tasks.

• Flexible sensor extends automation possibilities to processes that weren’t previously possible

• High-accuracy sensor technology provides 95% better quality in insertion and assembly tasks.

• Easy programming gets even complex polishing tasks up and running in less than a day

When starting a new robot automation project, In-Position Technologies engineers begin by reviewing the essential requirements to determine the optimum accessories need for the robot to perform the job. They perform all necessary engineering assessments to make sure the robot and its accessories perform as required, within customer specifications, and without unnecessary cost. They will also recommend the appropriate controllers, vacuum source, power supply, and sensor that fit the application.

This includes:

• Payload, reach, speed, cycle time, and repeatability requirement

• Ensuring compatibility with the current system

• Specifying the appropriate feedback device (sensors, vision system, torque sensor)

• Verifying mounting compatibility, form factor checks, etc.

• Ensuring all necessary auxiliary equipment are also specified

When ordering Hex 6-Axis Force/Torque Sensors as a part of a full system, IP Tech engineers review the solution to ensure:

• All parts and fittings necessary for a complete working solution are included

• All components have been checked and verified to work together as a system

• The selected components will perform as required by the project specifications