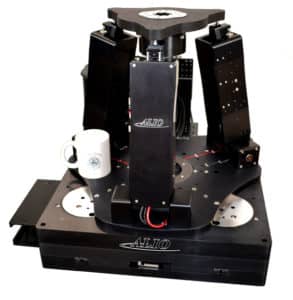

In 2001 ALIO designed, built and patented the first True Nano® precision Hexapod and Tripod robots.(US patents 6,769,194 and 6,671,975) Over the years the ALIO Hexapod has been the standard for nanometer applications requiring 5 or 6 axis robot. Keeping with the ALIO name a “Better and new way”, ALIO designed and built a novel patented Hybrid Hexapod which again exceeds all known 5 and 6 axis motion system performance, precision, and quality; with orders of magnitude more precision than even their own unmatched nano precision Hexapod.

• Increased work envelope and precision

• Increased stiffness, ideal for nano machining or thermal bonding applications where reactive forces are common.

• Packaged from 3 to 6 axes while maintaining ALIO forward and inverse kinematic equations

• MINI and 30° options available

When starting a new linear and rotary motion project, In-Position Technologies engineers start by reviewing the key requirements to determine the optimum positioner for the job. They perform all necessary engineering calculations to make sure the positioners perform as required, within customer specification, and without unnecessary cost. They will also recommend the appropriate controllers and drives that will best fit the application.

This includes:

• Motor torque, speed, and inertia matching

• Ensuring compatibility with the motor drive and available power

• Specifying the appropriate feedback device, encoder (incremental vs. absolute), resolver, etc…

• Verifying mounting compatibility, form factor checks, etc…

• Ensuring all necessary accessories are also specified

When ordering the Hybrid Hexapod as a part of a full system, IP Tech engineers review the solution to ensure:

• All parts and accessories necessary for a complete working solution are included

• All components have been checked and verified to work together as a system

• The selected components will perform as required by the project specifications