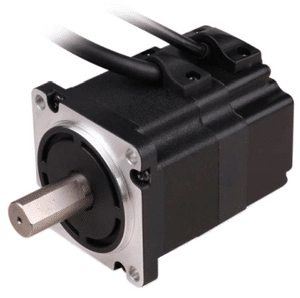

Hybrid Stepping Motors

Combining over 50 years of experience in the precise motor products industry for motion control, DINGS’ operates manufacturing facilities in both China and the United States, with service and support centers worldwide. This global presence enables DINGS’ to deliver quality, cost-effective product solutions to OEM customers in Asia, North America, and Europe. Their ability to create innovative custom solutions offers the flexibility needed to meet diverse application requirements.

• Size 8 (20mm) to Size 35 (86mm) frames

• 0.014 to 7.2 Nm holding torque

• Standard options for installed planetary gearbox and/or encoders

• Custom termination and wire/cable lengths

• Other customizations available on request

When starting a new stepper motor project, In-Position Technologies engineers start by reviewing the key requirements to determine the optimum size motor for the job. They perform all necessary engineering calculations to make sure the motor performs as required, within customer specification, and without unnecessary cost. They will also recommend the appropriate controllers and drives that will best fit the application and motor.

This includes:

• Motor torque, speed, and inertia matching

• Ensuring compatibility with the motor drive and available power

• Specifying the appropriate feedback device, encoder (incremental vs. absolute), resolver, etc…

• Verifying mounting compatibility, form factor checks, etc…

• Ensuring all necessary accessories are also specified

When ordering Hybrid Stepping Motors as a part of a full system, IP Tech engineers review the solution to ensure:

• All parts and accessories necessary for a complete working solution are included

• All components have been checked and verified to work together as a system

• The selected components will perform as required by the project specifications