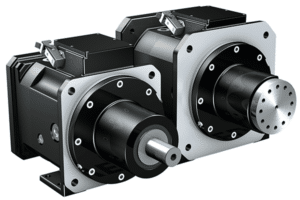

STOBER K-KL Series helical/bevel gear drives are the most versatile Servo right angle gearheads. With mounting flexibility and a variety of output options, they are the optimal drive when you need configuration choices. The K hollow bore can easily replace a belt and pulley, eliminating additional components and accessories. Every gearbox is made to order. STOBER will custom whatever you need to fit your application. Contact us today to learn more.

Features:

• 4:1 to 381:1 ratios (K) or 4:1 to 32:1 ratios (KL) (higher ratios available. Contact STOBER.)

• Quiet running (<51dB(A))

• Reduced backlash option for increased precision (K)

• Symmetrical design for universal mounting (KL)

• Mounting flexibility to fit the application

• Adaptability: shafts available in metric or imperial, carbon or stainless steel to meet your requirements

• Optional food and corrosion resistant package

• Dual seals for extreme duty applications

• Error free motor mounting and quick changeover with toleranced pilot on motor plate

• Magnetic oil filtration to remove contaminants to prevent breakdowns

• Build and ship in one day

• Assembled in the USA

When starting a new motion control project involving a gearhead, In-Position Technologies engineers start by reviewing the key requirements to determine the optimum gearhead type, gear ratio, and form factor for the job. They perform all necessary engineering calculations to make sure the system performs as required, within customer specification, and without unnecessary cost. They will also recommend the appropriate accessories that will best fit the application.

To ensure a gearhead fits the customer’s requirements, In-Position Technologies engineers review:

• Gear Ratio

• Gear Geometry

• Backlash

• Efficiency

• Weight

• Maximum Input RPM

• Nominal Output Torque

• Maximum Acceleration Output Torque

• Emergency Stop Torque

• Axial Load

• Radial Load

• Gearhead inertia at input

• IP Rating

When ordering the K-KL Series right angle gearheads as a part of a full system, IP Tech engineers review the solution to ensure:

• All parts and accessories necessary for a complete working solution are included

• All components have been checked and verified to work together as a system

• The selected components will perform as required by the project specifications