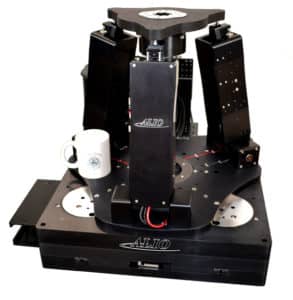

Linear Motion Systems

ALIO’s XY Monolithic True Nano® motion systems’ performance is unequaled for 6-D Nano Precision®. With nanometer straightness and flatness you can be assured that your point precision is True Nano®. This stage family is available from 25mm travel to 450mm travel. Standard axis bi-directional repeatability is less than 50 nanometers with optional 10 nanometers bi-directional repeatability for demanding metrology or manufacturing needs. Linear Motion Systems can come with NIST traceable data assuring nano precision is not just marketing data sheet optimism.

• Travel: 30mm – 440mm

• Velocity: up to 1m/sec

• Resolution: 5nm

• Bi-Directional Repeatability: ± 30nm

• Displacement Accuracy: 1 µm

• Standard and Highly Dynamic Grades

When starting a new linear and rotary motion project, In-Position Technologies engineers start by reviewing the key requirements to determine the optimum positioner for the job. They perform all necessary engineering calculations to make sure the positioners perform as required, within customer specification, and without unnecessary cost. They will also recommend the appropriate controllers and drives that will best fit the application.

This includes:

• Motor torque, speed, and inertia matching

• Ensuring compatibility with the motor drive and available power

• Specifying the appropriate feedback device, encoder (incremental vs. absolute), resolver, etc…

• Verifying mounting compatibility, form factor checks, etc…

• Ensuring all necessary accessories are also specified

When ordering Linear Motion Systems as a part of a full system, IP Tech engineers review the solution to ensure:

• All parts and accessories necessary for a complete working solution are included

• All components have been checked and verified to work together as a system

• The selected components will perform as required by the project specifications