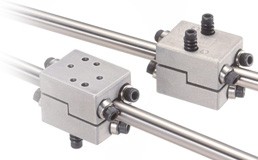

The NB Linear Shafts can be used in a wide range of applications as a mechanical component from straight shaft to spindle shaft. NB’s engineering expertise encompasses a wide range of manufacturing and machining capabilities for linear shafting, bearing rails and other equipment components.

Manufacturing options include:

• Various coatings, including chroming and ceramics, as well as repair and resurfacing services for older components

• A range of different materials, including high-carbon chromium bearing steel and Martensitic stainless steel

• Multiple product types, including NB SFW/SFWS/SN/SNS/SNT components and other high-precision shafts for our own slide bushings and bearings

When starting any new automation project, In-Position Technologies engineers start by reviewing the key requirements to determine all necessary components needed in an application. This includes providing recommendations for any appropriate controllers, power supplies, sensors, encoders, bearings, couplings, and any other components needed to fit the application. Our engineers perform all necessary engineering assessments to make sure all components perform properly together, are within customer specifications, and do not come with unnecessary costs.

This includes:

• Payload, reach, speed, cycle time, and repeatability requirement

• Specifying the appropriate feedback device (sensors, vision system, torque sensor)

• Verifying mounting compatibility, form factor checks, etc.

• Ensuring compatibility with the current system

• Ensuring all necessary auxiliary equipment are also specified

When ordering Linear Shafts as a part of a full system, IP Tech engineers review the solution to ensure:

• All parts and fittings necessary for a complete working solution are included

• All components have been checked and verified to work together as a system

• The selected components will perform as required by the project specifications