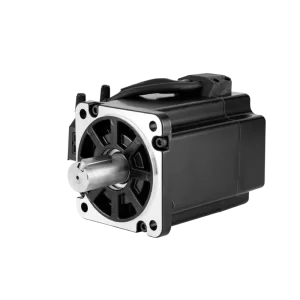

The TIM integrated servo motor is a cost effective and flexible solution, ideal for applications with limited control cabinet space and a decentral machine architecture. The TIM, with its high power density and compact size, enables space-saving machine designs and ultimately cabinet-less machines.

• Frame size: 60 – 80 mm

• 0.64 to 2.55 Nm rated output torque

• 200W to 800W rated output power

• 3 digital inputs, 1 digital output

• Fieldbus: CANopen, EtherCAT

• Feedback: Absolute single turn,

• Absolute multi turn

• 24VDC / 48VDC bus voltage

• IP54 protection class (IP65 optional)

• Motor holding brake (optional)

• Integrated design minimizes component and wiring requirements

• Integrated Functional Safety – STO or optional Safe Motion Module (Cat 3, PL e)

• CE and cUL certifications

When starting a project requiring an integrated servo system, In-Position Technologies engineers start by reviewing the key requirements to determine the optimum size motor for the job. They perform all necessary engineering calculations to make sure the motor performs as required, within customer specification, and without unnecessary cost. They will also recommend the appropriate controllers and drives that will best fit the application and motor.

This includes:

• Motor torque, speed, and inertia matching

• Ensuring compatibility with the system controller and available power

• Verifying mounting compatibility, form factor checks, etc…

• Ensuring all necessary accessories are also specified

When ordering TIM integrated servo motor as a part of a full system, IP Tech engineers review the solution to ensure:

• All parts and accessories necessary for a complete working solution are included

• All components have been checked and verified to work together as a system

• The selected components will perform as required by the project specification