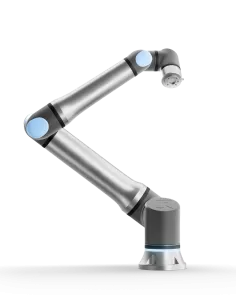

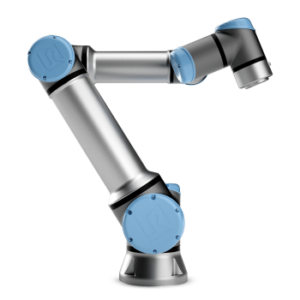

UR20

Universal Robots pioneers collaborative robots (cobots) that enhance automation, increase productivity, and ensure safe, flexible operations across diverse industries.

With a 1750 mm reach and 20 kg payload capacity, UR’s UR20 cobot handles more tasks, fits more applications, and assists in more environments than ever before. The UR20, part of Universal Robots’ next generation of industrial cobots, takes performance to new heights while maintaining UR’s versatility, usability, and small footprint.

BIG THINKING. THAT’S FAR REACHING.

The increased reach scales cobot automation and throughput gains for more demanding, heavier-duty applications.

PACKAGING AND PALLETIZING

For picking, packing, and palletizing heavy parts, the UR20 boosts efficiency and productivity. It reaches standard EURO pallets and stacks up to 2m high.

MACHINE TENDING

The UR20 processes larger dimension parts for machinery such as cutting, punching, drilling, machining, and forming. It mounts in any position and easily moves around workplace objects, including machine tending doors.

PERFORMANCE ON A WHOLE NEW SCALE.

Redesigned from the ground up, the software brings unprecedented motion control capabilities to the joint architecture. It achieves up to 30% greater speed and 25% higher torque within a closed capsule.

PART HANDLING AND ASSEMBLY

The UR20’s greater payload allows heavier workpiece handling and the option to configure multiple end effectors for better cycle times. It is ideal for manufacturing and assembling large equipment such as diesel engines, drivelines, transmissions, and battery assemblies, often requiring human-robot collaboration.

WELDING

In applications requiring long seams of parts and components, the UR20’s small footprint enables multiple robots to be used in the same production cell. The new joint architecture improves motion consistency, while the 1750mm reach geometry expands your work zone.