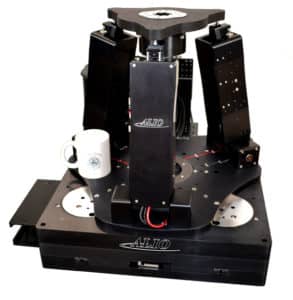

Z-Lift And Vertical Axis Motion Systems

ALIO Industries’ Z-Lift And Vertical Axis Motion Systems were created to replace the inaccuracies of the ever -present Z-Wedge vertical stages as well as reduce the footprint and improve performance of linear stages mounted in the vertical orientation. Every component in a motion stage adds to the total error. Since Z-wedges have a minimum of three machined components with complex angles, three sets of bearings, a motor via a coupling and an encoder, the result is a very inaccurate stage.

ALIO answers this with a family of very high accuracy, high repeatable vertical stages.

• Travel: 30mm – 440mm

• Velocity: up to 1m/sec

• Resolution: < 5nm

• Bi-Directional Repeatability: < ± 30nm

• Displacement Accuracy: < 1 µm

• Standard and Highly Dynamic Grades

When starting a new linear and rotary motion project, In-Position Technologies engineers start by reviewing the key requirements to determine the optimum positioner for the job. They perform all necessary engineering calculations to make sure the positioners perform as required, within customer specification, and without unnecessary cost. They will also recommend the appropriate controllers and drives that will best fit the application.

This includes:

• Motor torque, speed, and inertia matching

• Ensuring compatibility with the motor drive and available power

• Specifying the appropriate feedback device, encoder (incremental vs. absolute), resolver, etc…

• Verifying mounting compatibility, form factor checks, etc…

• Ensuring all necessary accessories are also specified

When ordering Z-Lift And Vertical Axis Motion Systems as a part of a full system, IP Tech engineers review the solution to ensure:

• All parts and accessories necessary for a complete working solution are included

• All components have been checked and verified to work together as a system

• The selected components will perform as required by the project specifications