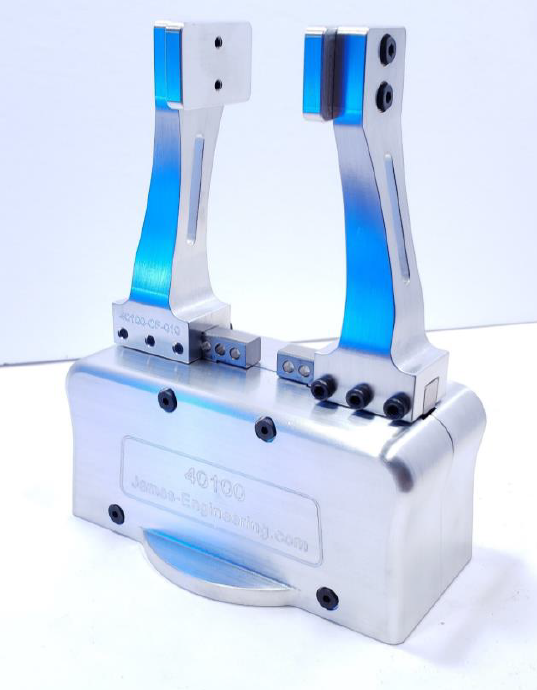

40100 Pneumatic Gripper System

The 40100 Pneumatic Gripper System is a comprehensive, highly adjustable and proven solution. It features interchangeable fingers and interchangeable pads. A wide range of off-the-shelf fingers and pads are in stock and ready to ship. Pads are available in many different materials ranging from 17-4 stainless steel, aluminum, to soft urethanes to ensure part protection

Precision-locating pins mount the fingers without any slop. The pins can be quickly removed in a few seconds to increase gripping size, shorten the finger length, change the height, etc.

Custom engineered solutions are available as well.

Feature:

• Super Low-Pressure Actuation – 10 psi for delicate light weight gripping

• Precision – low backlash

• Auto centering

• Interchangeable gripping fingers

• Interchangeable gripping pads

• Integrated rebuildable cylinder

When starting a new robot automation project, In-Position Technologies engineers begin by reviewing the essential requirements to determine the optimum accessories need for the robot to perform the job. They perform all necessary engineering assessments to make sure the robot and its accessories perform as required, within customer specifications, and without unnecessary cost. They will also recommend the appropriate controllers, vacuum source, power supply, and sensor that fit the application.

This includes:

• Payload, reach, speed, cycle time, and repeatability requirement

• Ensuring compatibility with the current system

• Specifying the appropriate feedback device (sensors, vision system, torque sensor)

• Verifying mounting compatibility, form factor checks, etc.

• Ensuring all necessary auxiliary equipment are also specified

When ordering the James Engineering 40100 Pneumatic Gripper System as a part of a full system, IP Tech engineers review the solution to ensure:

• All parts and accessories necessary for a complete working solution are included

• All components have been checked and verified to work together as a system

• The selected components will perform as required by the project specifications