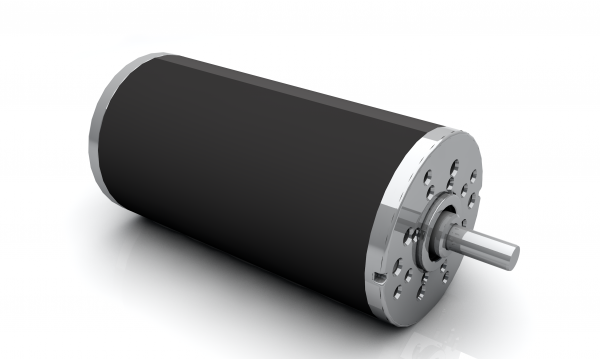

GR Series Brushed Servo Motors

Dunkermotoren develops and produces precision drives and has been in business for almost 70 years. They offer advanced brushed and brushless motion control solutions for a wide range of industrial automation applications, including factory equipment, office machines, medical devices and laboratory equipment. System solutions are based on brushless DC servo motors/brush-type DC motors, integrated power and logic controllers, planetary and worm gearboxes, and encoders and brakes. Markets include industrial automation, medical devices and laboratory equipment, door automation, motive, basic automation, and sun protection. View Additional Dunkermotoren Products

Dunkermotoren GR Series Brushed Servo Motors:

• Multi bar commutator for longer life

• Low detent torques and moments of inertia

• High efficiency

• Protection up to IP 67

• +12-60VDC

• 3 – 851W Nominal Power

• Easily combined with gearboxes, brakes, and encoders

When starting a new servo project, In-Position Technologies engineers start by reviewing the key requirements to determine the optimum size motor for the job. They perform all necessary engineering calculations to make sure the motor performs as required, within customer specification, and without unnecessary cost. They will also recommend the appropriate controllers and drives that will best fit the application and motor.

This includes:

• Motor torque, speed, and inertia matching

• Ensuring compatibility with the motor drive and available power

• Specifying the appropriate feedback device, encoder (incremental vs. absolute), resolver, etc…

• Verifying mounting compatibility, form factor checks, etc…

• Ensuring all necessary accessories are also specified

When ordering GR Series Brushed Servo Motors as a part of a full system, IP Tech engineers review the solution to ensure:

• All parts and accessories necessary for a complete working solution are included

• All components have been checked and verified to work together as a system

• The selected components will perform as required by the project specifications