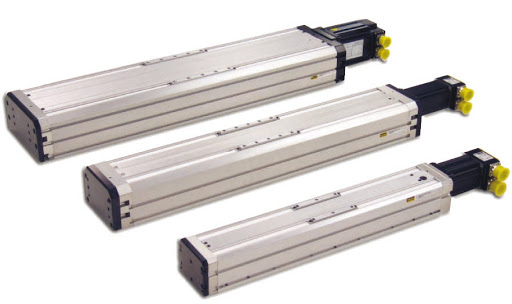

HD Series Linear Positioners

Parker Hannifin delivers precision motion and control solutions, enabling advanced automation, improved efficiency, and optimized performance across industrial and aerospace applications.

The HD Series Linear Positioners are designed for OEMs, Machine Builders, and End Users needing a robust positioning solution. The robust design begins with a deep channel extruded body and carriage that provide exceptional beam strength and carriage stiffness. The linear bearings and ballscrews are self lubricating, precision components with long life at 100% duty operation. The HD Series also includes IP30 rated belt seals that protect the interior components from debris in tough environments. The HD Series is the ideal solution for industrial positioning applications.

• As low as 8 micron bidirectional repeatability

• 24/7 operation at 100% duty

• Dowel holes for repeatable mounting

• IP30 rated protective belt seals

• Travels up to 2 meters

• Maintenance Free linear bearings and ballscrew

When starting a new motion control project involving a precision stage, In-Position Technologies engineers start by reviewing the key requirements to determine the optimum size actuator and level of precision required for the job. They perform all necessary engineering calculations to make sure the stage performs as required, within customer specification, and without unnecessary cost. They will also recommend the appropriate motors, controllers, and drives that will best fit the application selected actuator.

To ensure a precision stage fits the customer’s requirements, In-Position Technologies engineers review:

• Repeatability

• Positional Accuracy

• Straightness & Flatness

• Actuator thrust, travel, and motion profile calculations

• Life calculations given the load

• Ensuring compatibility with the motor

• Specifying the appropriate options such as environmental ratings and limit switches

• Verifying mounting compatibility, form factor checks, etc.…

• Ensuring all necessary accessories are specified

When ordering the HD Series Linear Positioners as a part of a full system, IP Tech engineers review the solution to ensure:

• All parts and accessories necessary for a complete working solution are included

• All components have been checked and verified to work together as a system

• The selected components will perform as required by the project specifications