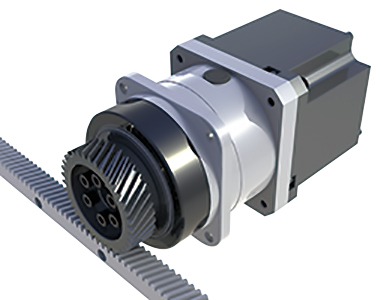

HPG with Rack & Pinion

The RK systems from Harmonic Drive are ideal for CNC machining centers, metal cutting machines, laser machines and high-precision milling machines. HPG Harmonic Planetary® gears with rack & pinion are available now. The HPG with rack & pinion system carries the reputation for quality and reliability for which Harmonic Drive® products are known throughout the world.

Key Features:

• High accuracy helical rack and pinion

• Higher positioning accuracy

• Runout accuracy of the pinion gear installed on the gearhead is 15μm or less

• Low noise and vibration due to ground finish helical rack and pinion

When starting a new motion control project involving a gearhead, In-Position Technologies engineers start by reviewing the key requirements to determine the optimum gearhead type, gear ratio, and form factor for the job. They perform all necessary engineering calculations to make sure the system performs as required, within customer specification, and without unnecessary cost. They will also recommend the appropriate accessories that will best fit the application.

To ensure a gearhead fits the customer’s requirements, In-Position Technologies engineers review:

• Gear Ratio

• Gear Geometry

• Backlash

• Efficiency

• Weight

• Maximum Input RPM

• Nominal Output Torque

• Maximum Acceleration Output Torque

• Emergency Stop Torque

• Axial Load

• Radial Load

• Gearhead inertia at input

• IP Rating

When ordering the HPG with rack & pinion as a part of a full system, IP Tech engineers review the solution to ensure:

• All parts and accessories necessary for a complete working solution are included

• All components have been checked and verified to work together as a system

• The selected components will perform as required by the project specifications