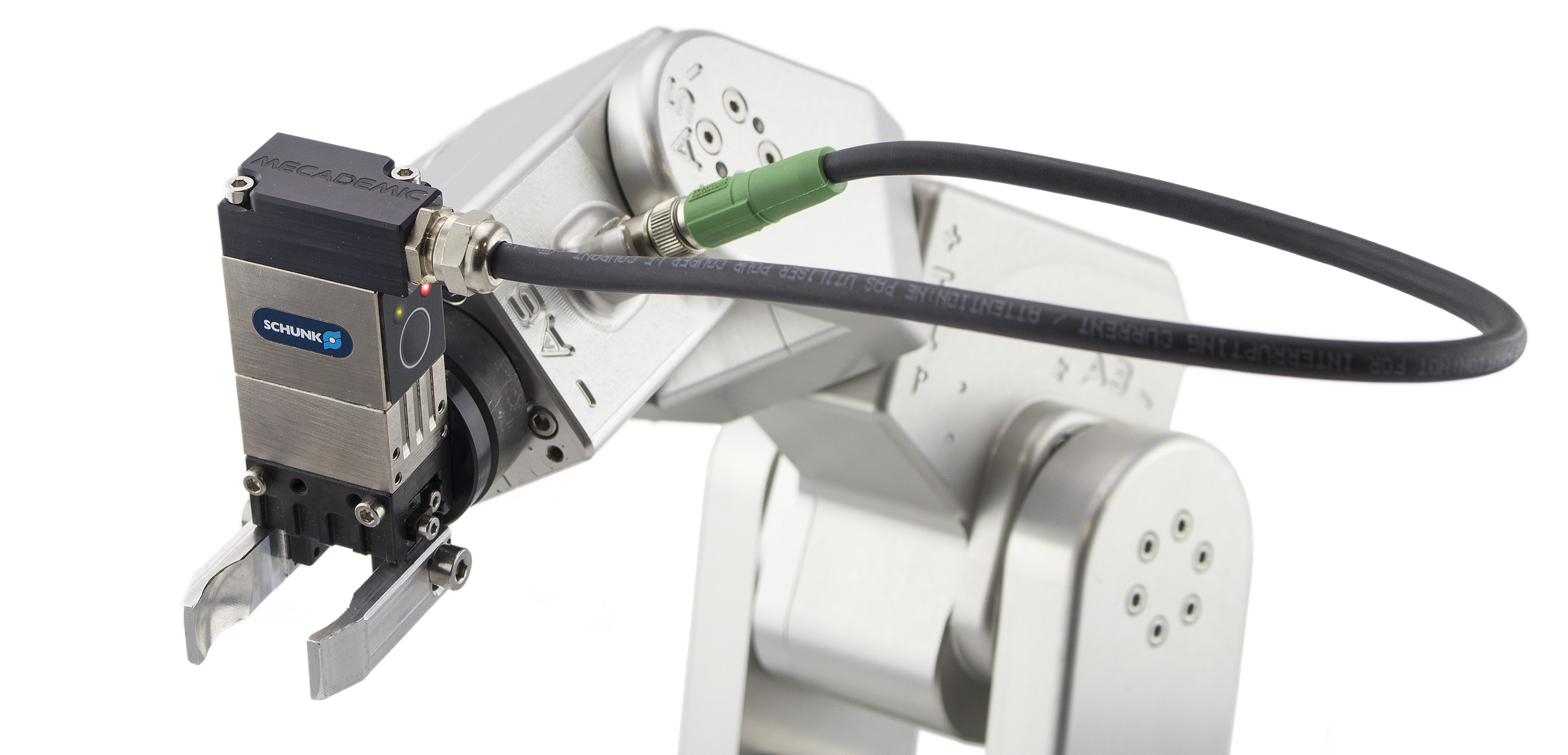

MEGP 25 Miniature electric parallel gripper

Mecademic provides ultra-compact, precise, and easy to integrate robot arms that will revolutionize the robotics field. An industrial robot should be a component, like a conveyor or a smart camera, not a bulky, stand-alone, and complex system that requires several days of training. Mecademic designs, develops and manufactures the smallest and most accurate six-axis industrial robots on the market. These robots are typically used for testing and inspection, material handling, assembly, and dispensing, mainly in the electronics and medical devices industries. View Additional Mecademic Products

This MEGP 25 Miniature electric parallel gripper is fully integrated with the Meca500 six-axis industrial robot.

•Stroke per jaw – 3 mm

•Recommended workpiece weight is 200 g

•Repeatability – 0.020 mm

•Weight – 120 g

•Max. admissible finger length – 32 mm

When starting a new robot automation project, In-Position Technologies engineers begin by reviewing the essential requirements to determine the optimum accessories need for the robot to perform the job. They perform all necessary engineering assessments to make sure the robot and its accessories perform as required, within customer specifications, and without unnecessary cost. They will also recommend the appropriate controllers, vacuum source, power supply, and sensor that fit the application.

This includes:

• Payload, reach, speed, cycle time, and repeatability requirement

• Ensuring compatibility with the current system

• Specifying the appropriate feedback device (sensors, vision system, torque sensor)

• Verifying mounting compatibility, form factor checks, etc.

• Ensuring all necessary auxiliary equipment are also specified

When ordering the MEGP 25 Miniature electric parallel gripper as a part of a full system, IP Tech engineers review the solution to ensure:

• All parts and fittings necessary for a complete working solution are included

• All components have been checked and verified to work together as a system

• The selected components will perform as required by the project specifications