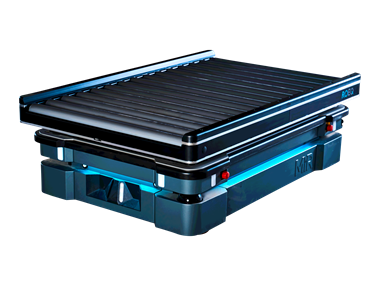

TR500

Top roller for heavier internal logistics in industrial facilities. The TR500 lets you automate loading and unloading operations and carry out scheduled pick-up and delivery tasks.

The rollers are braked during transport on the TR500 which ensures safety and security of goods and people. For further safety, there is a built-in barrier to protect fingers from being caught in the rollers.

Robot compatibility:

MiR500/MiR1000

ROEQ product compatibility:

DS Standalone

Payload:

MiR500: 500kg/1103lbs

MiR1000: 500kg/1103lbs

Size: 1435x938x110mm

Roller area: 1390mm/820mm – Side rails can be demounted, allowing the cargo to extend over the sides.

Height Floor to rollers: 450 mm ±3 mm

Three types of built-in sensors:

Optical – identify the stationary conveyor station, ensuring precise alignment

Front payload – ensure that the robot doesn’t miss out on receiving packages from the stationary station and prevents dangling packages before the robot takes off

Rear payload – detect and stop the package and roll it back slightly to ensure optimal placement on the top roller

In-Position Technologies is proud to support MiR and AutoGuide’s full line of Mobile Robots and is ready to help customers find the right robot for their application. With payload, and size variation, all of In-Position Technologies’ Robots are ready to hit the ground rolling for warehouse logistics automation.

Multiple Configurations Available (looking for something specific? Contact us for other options):

• Various Payloads

• Tugger/Stacker Configuration

Standard Options Include:

• AMR Capabilities

• LiDAR Scanners and Mapping Systems

• Zero invasive infrastructure

Examples of available custom features:

• WiFi Modules

• Custom Top Modules for various applications

• Supply Carts

When starting a Mobile Robot project, In-Position Technologies engineers review the applications’ key requirements to determine the optimum size robot for the job. They perform all necessary engineering calculations to make sure the robot performs as required, within customer specification, and without unnecessary cost. They will also recommend the appropriate top modules and accessories to best fit the application.

This includes:

• MiR Hooks for custom and existing carts

• MiR Pallet Lifts

• Pallet Docks

When ordering the TR500 as a part of a full system, IP Tech engineers review the solution to ensure:

• All parts and accessories necessary for a complete working solution are included

• All components have been checked and verified to work together as a system

• The selected components will perform as required by the project specifications